Material handling is the lifeblood of countless industries, from e-commerce fulfillment centers to sprawling construction sites and manufacturing plants. It encompasses the movement, protection, storage, and control of materials and products throughout their lifecycle. The efficiency of these processes is directly tied to the equipment you use. Selecting the right material handling equipment is not a one-size-fits-all endeavor; it is a strategic decision that impacts everything from throughput and labor costs to workplace safety and floor space utilization.

This guide provides a comprehensive overview of the main categories of material handling equipment, their applications, and key considerations for building a smarter, more efficient operation.

Core Categories of Material Handling Equipment

Understanding the landscape of available equipment is the first step to optimization. These systems are generally broken down into four key categories.

1. Storage & Handling Solutions

This category includes the static infrastructure that organizes your space and makes inventory accessible.

- Pallet Racking: Selective, drive-in, push-back, and pallet flow systems each offer different density and accessibility trade-offs.

- Shelving & Lockers: Ideal for smaller items, tools, and parts in industrial and facility settings.

- Mezzanine Floors: Effectively create a second story within your existing facility, dramatically increasing storage capacity without expanding your footprint.

2. Bulk Material Handling Equipment

For operations dealing with loose, unpackaged materials like aggregate, grain, or chemicals.

- Conveyor Systems: Belt, roller, and chain conveyors automate the horizontal movement of goods, reducing manual labor.

- Hoppers & Silos: Used for the storage and controlled discharge of bulk materials.

- Stackers & Reclaimers: Massive machines used in industries like mining and shipping for handling bulk stockpiles.

3. Industrial Trucks & Transport

This is the mobile equipment used for moving loads throughout a facility.

- Forklifts: The workhorse of the industry, available in electric, LPG, and diesel models for various indoor and outdoor applications.

- Pallet Jacks: Both manual and electric walkie riders for efficient horizontal transport of palletized goods.

- Platform Trucks & Tow Tractors: For moving non-palletized loads or pulling a series of carts.

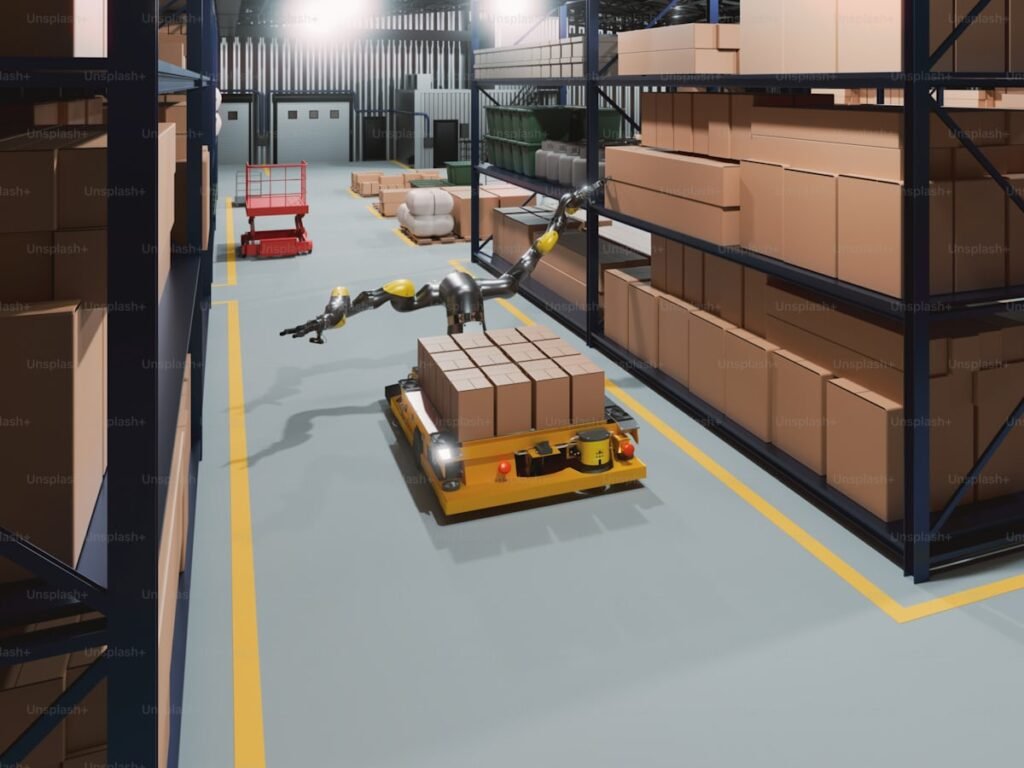

4. Engineered Systems & Automation

The frontier of material handling, these are automated, integrated systems that minimize human intervention.

- Automated Storage & Retrieval Systems (AS/RS): Computer-controlled systems that automatically place and retrieve loads from defined storage locations.

- Automated Guided Vehicles (AGVs) & Autonomous Mobile Robots (AMRs): Self-driving vehicles that transport materials without a human operator.

Key Selection Criteria: Building Your Equipment Strategy

Choosing the right equipment requires a careful analysis of your specific needs. Consider these factors:

| Factor | Key Questions to Ask |

|---|---|

| Load Characteristics | What is the weight, size, and shape of the materials? Are they palletized, packaged, or loose? |

| Flow & Throughput | What is your required daily/weekly volume? How quickly do materials need to move through the system? |

| Facility Constraints | What are the ceiling heights, aisle widths, and floor conditions? Are there any door or elevator limitations? |

| Ergonomics & Safety | How can equipment reduce manual handling and strain on workers? What safety features are critical? |

| Total Cost of Ownership | What are the long-term costs for maintenance, energy, and potential future expansion? |

The Critical Role of a Knowledgeable Supplier

Navigating this complex landscape is challenging. The right supplier acts as a consultant, helping you match the correct technology to your unique operational puzzle. A provider known for comprehensive and reliable Verdex Equipment can offer invaluable guidance, ensuring you invest in solutions that deliver not just immediate performance, but also long-term reliability and scalability. The goal is to create a cohesive material handling ecosystem where each piece of equipment works in harmony with the others, driving productivity and safety to new heights.